Pre-Filled Syringe

Plastic Prefillable

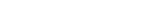

ClearJect® Syringe

Cyclo Olefine Polymer (COP)

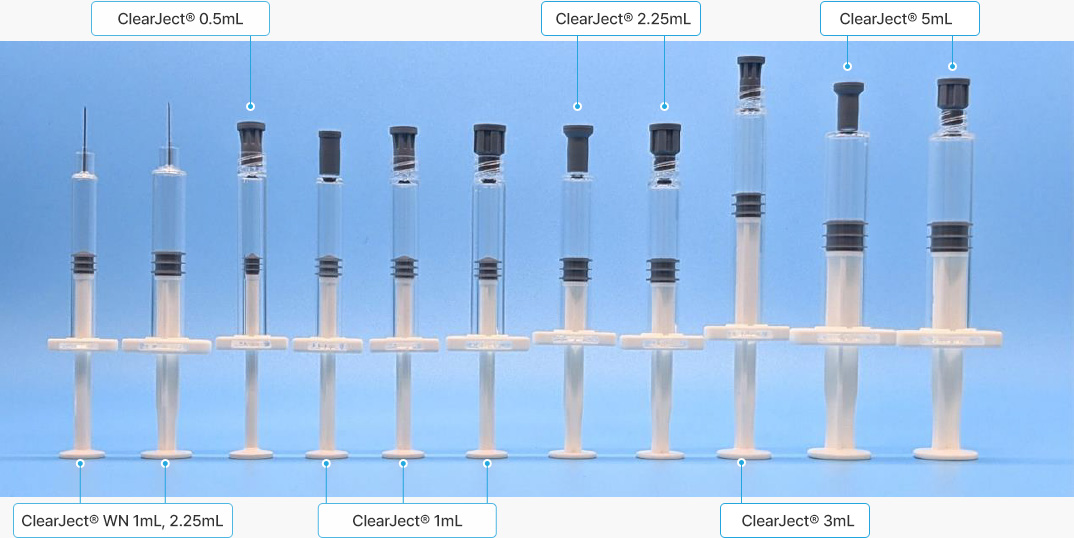

파트 명칭 및 재질

플라스틱 주사기

Clearject® COP

- 일본 TAISEI KAKO사의 플라스틱 프리필드 주사기

- 모든 공정 자동화 시스템 (Clean room 진행)

- Sterilization : 감마멸균 (Barrel, Tip cap, Piston)

- Barrel : Cyclo Olefine Polymer 소재 (감마멸균)

- Tip Cap / Piston : Butyl Rubber 소재 (감마멸균)

- ISO13485 인증 생산시설

- Damage / Cracking에 우수

- Siliconization : 12,500cSt. 의료등급 실리콘 사용

- Inspection : 100% 카메라 검사 수행

- Packing : Ready-To-Use (RTU) 포장

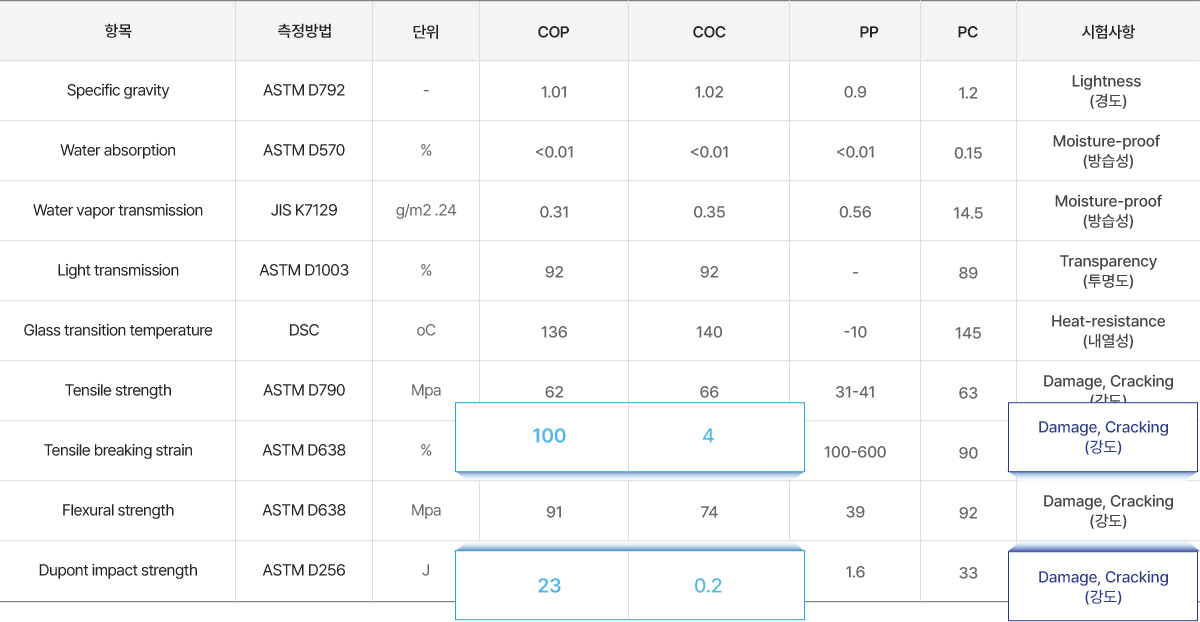

Cyclo Olefine Polymer (COP)

플라스틱 주사기 재질 특성 비교

감마 멸균 완료 플라스틱 주사기

Barrel(COP)

Cap/Piston(Butyl Rubber)

감마멸균 완료 후

Packing

- 다양한 멸균 호환 가능

-

AutoclaveEthylene Oxide GasElectron Beam

감마멸균 진행에 따른 Barrel (COP)의 색 변화

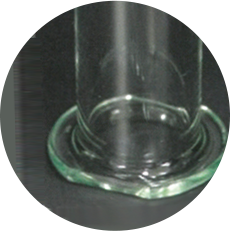

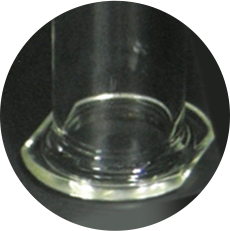

Non-irradiated barrel

25kGy

irradiation

One week has passed

Four weeks have passed

Biological safety test

생물학적 안정성 시험 통과 완료

Tested object

- ISO10993 Biological evaluation for Medical devices

- External communicating device, blood path, indirect ← 24h

Testing method

- COP-barrels, Butyl rubber pistons, PTDE-laminated pistons, SUS304-canulas

| Evaluation items | Judgement |

|---|---|

| Acute toxicity test with rats | Accepted |

| Skin sensitization with guinea pigs | Accepted |

| Cell toxicitytest with rabbits | Accepted |

| In vitro hemolysis toxicity test with rabbits blood | Accepted |

| Intradermal skin test with rabbits | Accepted |

| Pyrogen test with rabbits | Accepted |

Exractables Assessment

용출물 평가 시험 통과 완료

- USP1663

-

- -Assessment of Extractables Associated with Pharmaceutical

- -Packaging / Delivery Systems

Tested object

COP barrel, Butyl rubber piston, Teflon-film coating piston

Analysis

Extraction medium : aqueous, organic solvent etc.

Detected compounds

- γ-Ray irradiation sterilized COP barrel : Total over 34

- Autoclave-, γ-Ray irradiation- and autoclave-steriliazed butyl - rubber piston : Total over 47

- Twice autoclave-steriliazed Teflon-film coating piston : Total over 65

Toxicity assessment

Judgement as non-toxic material compared with toxicity data

ISO13485 인증 생산시설

ISO 인증 및 FDA 등록 완료

-

License Number: 27B2X00203 (1" Sep., 2015)

Marketing Authorization Holders for Second-Class Medical Device -

License Number: 27BZ200369 (21 May, 2015)

Medical Device Manufacturing License -

License Number: 27AZ200113 (21 May, 2015)

License for manufacturer of drugs (Sterile products) by MHLW

-

ISO13485:2016

Certification Number: JP19/040500 -

ISO 14001:2015 (SGS 14001:2015)

Certification Number: JP18/071554 -

DMF(Drug Master File) Registration for US-FDA

Manufacturing of Plastic Syringes: DMF21350

Manufacturing of Plastic Syringes with Needle: DMF29071

Ready-To-Use 포장

TASPACK®

ISO 8등급 환경에서 성형 되고, ISO 7등급 환경 자동화 시스템에서 포장되어, Barrel과 Tip-cap이 결합된 RTU (Ready-To-Use) 상태로 포장됩니다.